Applying wax beading or starter strips to Warré top-bars

This is very similar to Warré's second method in Beekeeping For All ( http://www.users.callnetuk.com/~heaf/beekeeping_for_all.pdf page 77 ).

Melt wax in a bain marie on a cooker.

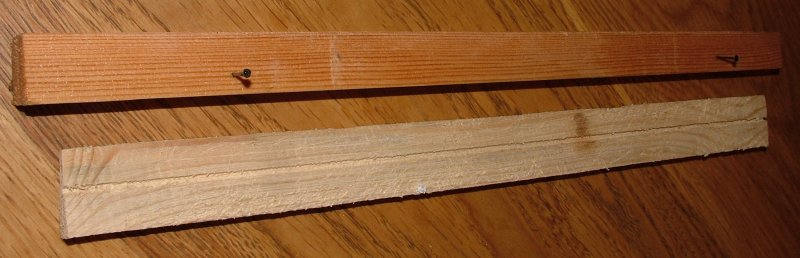

24 x 9 mm top-bar, rough underneath, 2 x 2 mm groove down middle (bottom).

Waxing template (this one 18 x 14 mm) with two frame pins placed 12 mm from the 12 mm edge

(top).

The groove is not essential. It is not mentioned in Warré's book but is a modification introduced by Jean-Claude Guillaume. Warré recommends leaving the underside of the top-bar rough sawn to improve wax stickability. The upper side is planed.

Thorougly soak the template in water (Warré suggests adding honey to the water, method 1 p 77). Drain off excess water and place template on top-bar using pins (now underneath) as a guide. Right-handers hold it in the left hand.

Pour wax from teaspoon (bent at end to form a spout) aginst the template hilsing the bar at a tilt so wax runs into the groove and against the template. Let wax set.

Wax in groove of top-bar and resting against damp template.

Wax beading or starter strip (rear), template removed (front).

Re-wet the template and do the next bar.

The author has found that 22 g wax does 8 bars. Another Warré beekeeper found that 28 g wax does 8 bars. Still another managed to make a beeswax candle of approximately 60 g suffice for 4 boxes of 8 top bars each.

Bill Wood (Oregon) recommends warming the top-bars before applying the wax in order to help penetration of the wax into the pores of the wood.

Alternative method to deliver the molten wax

Joe Waggle uses a wax pipette to deliver the wax to the top-bar. It works similarly to a common kitchen tool used for basting meat.

The metal tube is dipped in the molten wax in a suitable container in a bain marie. The hole at the bottom admits wax and displaces air through the hole in the handle. The thumb is then placed over the hole. The wax in the pipette is then transferred to the top-bar and allowed to run out under control by releasing the thumb to the degree desired.

Joe Waggle describes the tool: It is comprised of a 6 inch long 3/4 inch copper pipe. One end has a 'V' cut and is hammered into a funnel point and soldered, with a 1/8 inch hole at the end. The other end has a wooden handle wedged into the 3/4 inch pipe and is sealed in place with glue. There is a 1/8 inch hole in the wooden handle that leads to the interior of the copper pipe.

This device is also available commercially:

Wax tube fastener

https://www.dadant.com/catalog/product_info.php?products_id=231

http://beekeeperlinda.blogspot.com/2007/03/sad-saga-of-wax-tube-fastener.html

The following video describes how the wax tube fastener is used:

http://www.youtube.com/watch?v=vIoeCPWP6AE

Another method

http://www.youtube.com/watch?v=31ovKSO-v4g