Bentwood and reeds trough with

cork-lined ends and entrance hole

Bentwood and reeds trough with

cork-lined ends and entrance holeDavid Junker's bentwood and reeds trough hive

The hive was kindly presented to me by David Junker. His own web page for his hive is here.

Construction

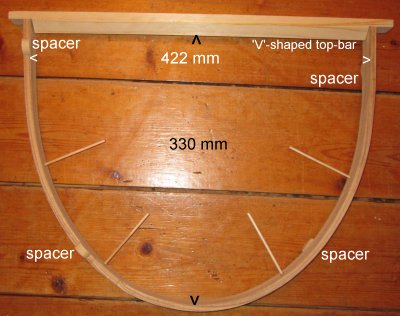

The wooden body frame is made from ash bent after heating in a steam chamber and clamped on formers until fully cooled. Between the inner and outer 'U'-shaped members of the frame is sandwiched a reed mat stabilised with stainless steel wire. Such mats, 5, 100, 200 cm in size, can be bought from ecological building materials suppliers. The inner 'U'-shaped end boards comprise 20 mm softwood inside, clad with 25 mm compressed cork board. The hive is designed for warm-way operation with a 40 mm diameter entrance tunnel in softwood at one end. The 15 ash frames, detailed below, are fitted with comb supports made of bamboo and spacers. The semicircular spacers on the frames give 35 mm between frame centres. An additional frame, analogous to a dummy board or division board, is fitted with an acrylic sheet to enable comb development monitoring without disturbing the brood nest. The top-bars are covered with an organic linen cloth, topped with a 25 mm thick sheet of fibreboard for insulation. On this rests the curved wood-framed aluminium roof, which, like the Warré hive roof, is designed for ventilation of the loft cavity. The roof overhang is 140 mm at the front and back, and 70 mm at the sides.

The hive has remarkable similarities to an inverted skep with easily inspectable combs.

Matthäus Junker has provided calculations (in German) showing that the heat loss from David Junker's reed hive is less than half that of a hive with all softwood walls of 25 mm thickness and the same surface area. Note that the calculations take into account the thermal resistance of the inside and outside surfaces, as well as that of the wall material. A PDF of the calculations, together with hygrological considerations is downloadable here.

Cloaming

The hive arrived fully built apart from the roof and stand which were easy to assemble, but David Junker advised cloaming the exposed reeds in the traditional manner used for skeps. I used Matthias Thun's cloam recipe comprising clay (1 part), fresh cow manure (1 part), sieved wood ash (1/2 part) and whey as required. The clay was dug from a local outcrop and required much kneading with water before it was soft enough to use.

Bentwood and reeds trough with

cork-lined ends and entrance hole

Bentwood and reeds trough with

cork-lined ends and entrance hole

Below left: cloam ingredients Centre: mixing cloam Right: applying cloam

Below: partly cloamed hive

Below left: inside of roof Below right: a frame showing spacers and comb supports

The roof is a curved piece of aluminium on a curved frame comprising a bentwood batten at each end joined by five rafters dowel-jointed to the ends, and with a rectangular frame attached below forming eaves that loosely enclose the hive body's top.

The whole comb area on the partly semicircular frame is estimated by dividing the inside of the frame into a rectangle 120 x 420 mm at the top with a near-semicircle of 210 mm radius below it. This gives 1196 cm2 per frame, 17,740 cm2 for 15 frames and 35,880 cm2 for both sides of each comb. By comparison, an 11-frame British National brood box has 14,234 cm2, and a 22-frame Einraumbeute (golden hive) 50,138 cm2. Volumes occupied by fully built comb in all three hives are: reed trough 62.8 litres, National 24.9 litres, ERB 87.7 litres.

Below left: 4 frames and the acrylic division board in place Below right: 25 mm fibreboard in place

Below left: the complete hive Below right: bait hive

14 June 2021 -- populating the hive with a swarm

Swarming normally starts here at the beginning of May and reaches its first peak around 20 May. It was a 6-week wait before the first swarm became available when it entered the bait hive on the front porch of our house (see photo above right). Unfortunately it weighed only 0.75 kg. One around 2 kg would have given a better start. But with the paucity of swarms so far this season, it seemed best to make use of it. It could be united with another at a later date if one becomes available. The swarm was run in at dusk up a board positioned at the reed hive entrance. This proved very slow because, unlike with Warré and other hives with separate floors, the entrance, 40 mm diameter, could not be enlarged for the run-in. Shaking the swarm in would have been much quicker and will be the method used in future. To minimise bees rushing out in the morning and returning to the bait hive site which is only about 250 metres away, loose grass was piled in front of the entrance hole so that bees emerging would have to push their way through it and likely take note of the changed circumstances.

15 June 2021

By the next morning the swarm was clustered on the front wall of the hive below frames 1-3.

16 June 2021

A neat cluster had formed centrally under the first frames. The day began with rain, which was forecast to continue all day, so it was felt necessary to feed. The bee chamber was reduced from 8 to 5 frames and 2 kg of sugar as 2:1 syrup was given in a tub positioned beyond the acrylic follower board. The tub was covered with wine corks to prevent drowning, and sticks were inserted to ease access from the hive walls. About 3 dozen bees returned to the site of the bait hive. These were collected into a portable vacuum cleaner and shaken onto the top of the feed tub immediately before replacing the linen top-bar cover cloth, insulation board and roof.

22 June 2021

Nest now extending to 5 frames.

First pollen loads seen coming in. A 1.3 kg swarm came into a bait hive the same size as a National brood box. As the original swarm used in the reed hive was somewhat small (0.75 kg) in relation to the hive body, this new swarm was united with it over newspaper using the setup illustrated below, after extending the nest of the colony from 5 to 9 frames to accommodate the footprint of the National super.

A National super was placed on newspaper on the top-bars of the reed hive and all remaining access points at the top of the hive blanked off with pieces of wood. The swarm hanging from the lid of the bait hive was dumped into the super, covered with a National crown board fitted with a Porter escape, and the box with the rest of the swarm inverted on the crown board. The escape allowed the remainder of bees to join their swarm.

23 June 2021

Pollen still coming in, even in drizzle. By afternoon all bees had gone down into the National super and the bait hive box was removed. There was considerable increase in entrance activity, suggesting that uniting was progressing, but no pieces of newspaper were being ejected, a usual sign of uniting progress. This could be partly due to the reed hive entrance being half-way up the front face.

24 June 2021

Approximately one hundred and fifty dead bees in front of the hive entrance indicated that fighting had taken place overnight. Uniting had clearly not gone smoothly, so intervention was now required. The incoming swarm was clustered in the corner of the super. Unoccupied frames next to the established colony were temporarily removed and the swarm shaken into the space created while smoking the bees vigorously. The super was removed, the next reduced to 8 frames and the hive closed up. By late afternoon a single cluster had formed on the combs.

25 June 2021

The cluster now extends to 8 frames. As it is raining, there is almost no entrance traffic.

25 June 2021

Small amounts of pollen coming in during recent days.

4 July 2021

Hand sized patch of capped brood on frame 2 counting from entrance. Comb building on 5 frames.

https://www.youtube.com/watch?v=2pKeBQpWFM0

15 July 2021

A glance at the colony revealed that the rear combs visible through the follower board were devoid of bees, so a full inspection was done. The colony population was greatly reduced and there were recently hatched emergency queen cells on combs 1 & 2 counting from the entrance, with no sign of worker brood. It looks like there was queen loss, possibly during the uniting process, and one of the emergency queens took a swarm with her. The colony was apparently foraging satisfactorily and bringing plenty of pollen in.

23 July 2021

To remedy the hive's apparent queenlessness, a swarm was shaken in. There was some fighting but normal foraging was in progress the following afternoon.

29 September 2021

Ivy flow in progress. Much ivy pollen coming in. Fed 2 kg sugar as 2:1 syrup in a pot with floating wine corks and placed between the follower screen and the rear of the hive. Twigs were placed in the pot and against the hive wall to facilitate access for the bees.

10 October 2021

Fitted mouse guard (photo below). It comprises a 60 mm diameter wooden disc secured over the 38 mm entrance hole with two brass screws which in turn are fitted with 7 mm spacers cut from 10 mm copper pipe. This creates an annular entrance. When fitted there was a busy ivy flow in progress and the changed entrance configuration obviously created some confusion for the returning foragers.

10 April 2022

Mouse guard removed. Internal inspection: brood nest already expanded to the seam of bees between frames 4 and 5 from the entrance.

11 July 2022

Inspection: bees on 11th comb from entrance; plenty of space for expansion. Attempted to straighten cross-comb; some pieces of comb dropped.

24 September 2022

Harvested surplus honey. 5 brood frames with approximately 150 mm honey dome at the top were left near the entrance. A sixth frame full of honey was placed against these; then came the transparent follower board. The mouse guard was refitted. Because of the cross combing, three frames of honey comb had to be lifted as a unit. They were carried a little distance from the apiary and the honeycomb cut into a plastic container. The yield was 10.9 kg comb and honey. There was no trouble from robbers. The images below show comb being extracted, part of which dropped during the attempted straightening of cross comb.

28 May 2023

The colony was expanding rapidly in a long spell of good weather. Comb had been built right to the follower board. It was moved to the back, i.e. furthest from the entrance and brood nest and empty frames inserted. In disturbing frames with new comb and honey, some comb fell to the bottom.

16 November 2023

The colony had filled combs right to the follower board. The rearmost 5 combs were coross-combed, i.e. welded together. These were slid to a position behind the follower board. Then two battens were screwed to the frames (see photo) and all 5 frames lifted out together using a frame lifter. After extraction the yield was 11 kg honey.

References

Thun, M. K. Die Biene -- Haltung & Pflege. M. Thun Verlag, 6th edition, 2015.