1. Supers brought home for extracting their honey

Extracting honey

1. Supers brought home for extracting their honey

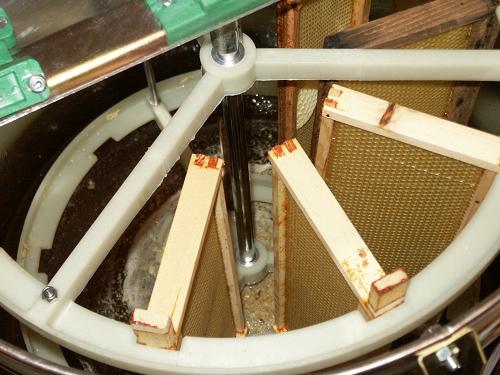

2. Radial extractor with some frames honey and froth at bottom

3. Close-up of Saf Natura 9-frame radial extractor containing comb frames with honey and froth at the bottom

4. Saf Natura 9-frame radial extractor lid open with frames inside plus frame closeup

5. Saf Natura 9-frame radial extractor with comb & cappings & uncaping fork

6. Honeycomb cappings in bowl and uncapping fork in action and extractor behind

7. Ripener tap and filled honey jars

8. Ripener tap and filled honey jars fairly closeup resting on a 3-frame nucleus beehive

9. Ripener tap and filled honey jars closeup

This beekeeper prefers to make the regular apiary visits by bicycle. When the equipment to

be transported is heavy and/or bulky he uses a trailer. The trailer shown in the first

picture is a Bykaboose Gecko (www.bykaboose.com, IL, USA) with the superstructure replaced

by a fish box which was found washed up on the coast. The fish box neatly fits the

'National' hive boxes used. In the trailer in the picture are two shallow boxes or

'supers' containing the frames of comb with honey. The payload of this trailer is about

40kg, sufficient for at least two completely full supers.

The next four pictures show the stainless steel Saf Natura manual 9-frame radial extractor

( www.safnatura.com ) used to centrifuge the honey

out of the comb. The wax cappings of the comb are first removed with an uncapping fork

(pictures 5 and 6). The frame is then placed in the rotor of the extractor with the

normally horizontal top bar of each frame now in a vertical orientation towards the wall

of the extractor. As the bees make the cells in the comb slope slightly downwards from

their openings (presumably to prevent nectar from running out), when the rotor is set

spinning with the frames in this orientation by turning the handle on the extractor, the

cells behave like thousands of little buckets being tipped to empty them. The rotor is

turned until no more droplets of honey fly against the outer wall of the extractor. The

honey runs down the wall and collects in the bottom of the extractor (visible in the

second picture). It is removed through a tap (not shown) near the base.

The honey, which at this stage contains many small pieces of wax from the cappings, is

transferred to a stainless steel strainer (not shown) which sits in the top of the

'ripener', the stainless steel urn shown in the 7th picture. It is then left overnight to

allow the many small air bubbles and wax particles small enough to pass through the

strainer to rise to the surface. If the crop is especially big it is stirred in the

ripener first to ensure uniformity of the bottled product. The honey is poured into one

pound jars using the tap at the bottom of the ripener and the lids are screwed in place.